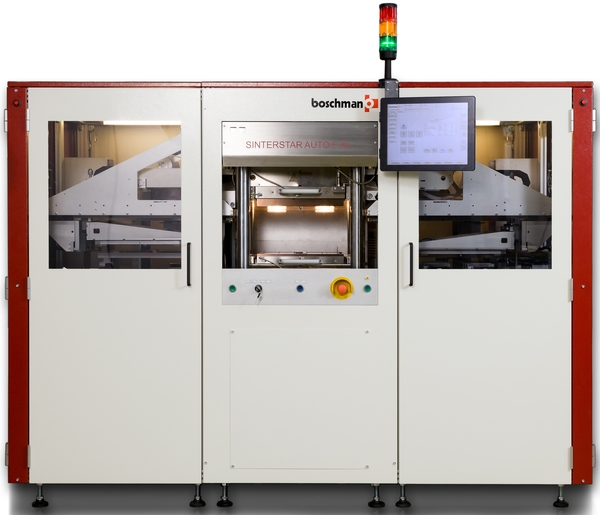

SINTERSTAR Inline-F-XL / Inline F-XL-HC / Auto-F-XL-HC

- Fully-automatic Ag sintering systems offering the absolute highest throughput available on the market

- Capable of sintering a wide range of different devices: LEDs, Power Devices Clip/heatsinks assemblies, solar (CVP) cells, custom designed power modules and more

- Largest sinter area – 350 x 270 mm

- Precise process-control and monitoring

- Systems can be equipped with a large variety of sintering tool concepts

- The Inline-F-XL is an economic sinter system designed to fit into your automated assembly line

- The fully-automatic Inline-F-XL-HC can be integrated into your automated assembly line and is equipped with preheating and cooling stations

- The fully automated and stand-alone Auto-F-XL-HC works from cassette input to cassette output and is equipped with preheating and cooling stations

- Dynamic insert control unit for controlled and predictable bond strength

- Oxidation prevention systems available

SINTERSTAR Innovate-F-XL

- The most universal semi-automatic sintering system for all your green, lead-free die attach technologies

- Silver sintering is a new die attach technology offering a void-free and strong bond with high thermal and electrical conductivity, resulting in high yield and high reliability

- Sinters a wide range of different devices including led, power, igbt, qfn, clip/heatsinks, thyristor and custom designed power module devices

- The Sinterstar Innovate-F-XL offers the largest sinter area (350 x 270 mm) and precise temperature control up to 320 C

- Our unique high-precision dynamic-insert pressure-control technologies allow you to sinter multiple dies with different die thicknesses resulting in a controlled and predictable bond strength

- Top film protection

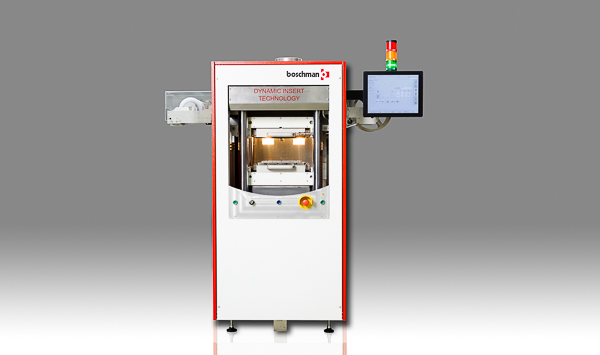

SINTERTOOL SOLUTIONS

- Ag sintering requires highly-customized tooling solutions

- Boschman offers a wide range of Sintertool solutions that fit on all of their sintering systems

- The core technology is dynamic insert technology (patented) which provides flexibility and maximum control

- The sintering pressure is precisely controlled and monitored during the complete sintering process and is programmable via the MMI (man-machine-interface)

- Dynamic controlled inserts automatically compensate for die height differences, resulting in a controlled and predictable sinter force