MicroAssembly Technologies, Ltd. (MAT) specializes in innovating and manufacturing die attach machines for microelectronics assembly. Their specific strengths are with complex, high-value applications. The company was founded in 2000 and is located in Israel.

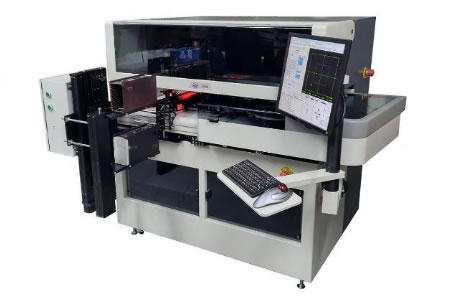

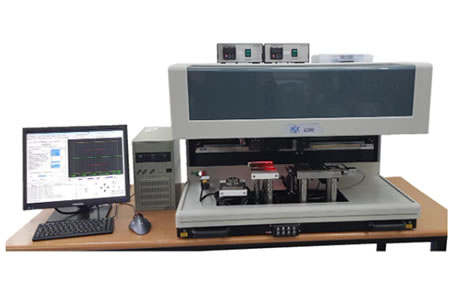

Their systems are a great fit for high-mix low-volume applications. NDC International offers MAT’s two current systems: