We are pleased to inform you that NDC is now representing Trim Form Automation (TFA) Europe! TFA Europe is focused on addressing the challenges in power module trim and form automation. The company grew out of Tooling Specialist Derksen (TSD). TSD is a respected supplier of precision mechanical parts and tools with over 20 years of experience in the design and manufacture of trim and form tools.

In recent years TSD has had success with several prototype and production trim and form tools for power modules. They recognized that power modules demanded innovation in product handling and controlled trimming and forming operations that is further complicated by additional processes like optical inspections and laser marking. To address the need for automation, TSD established Trim Form Automation (TFA) Europe and introduced the TFA Flex Line.

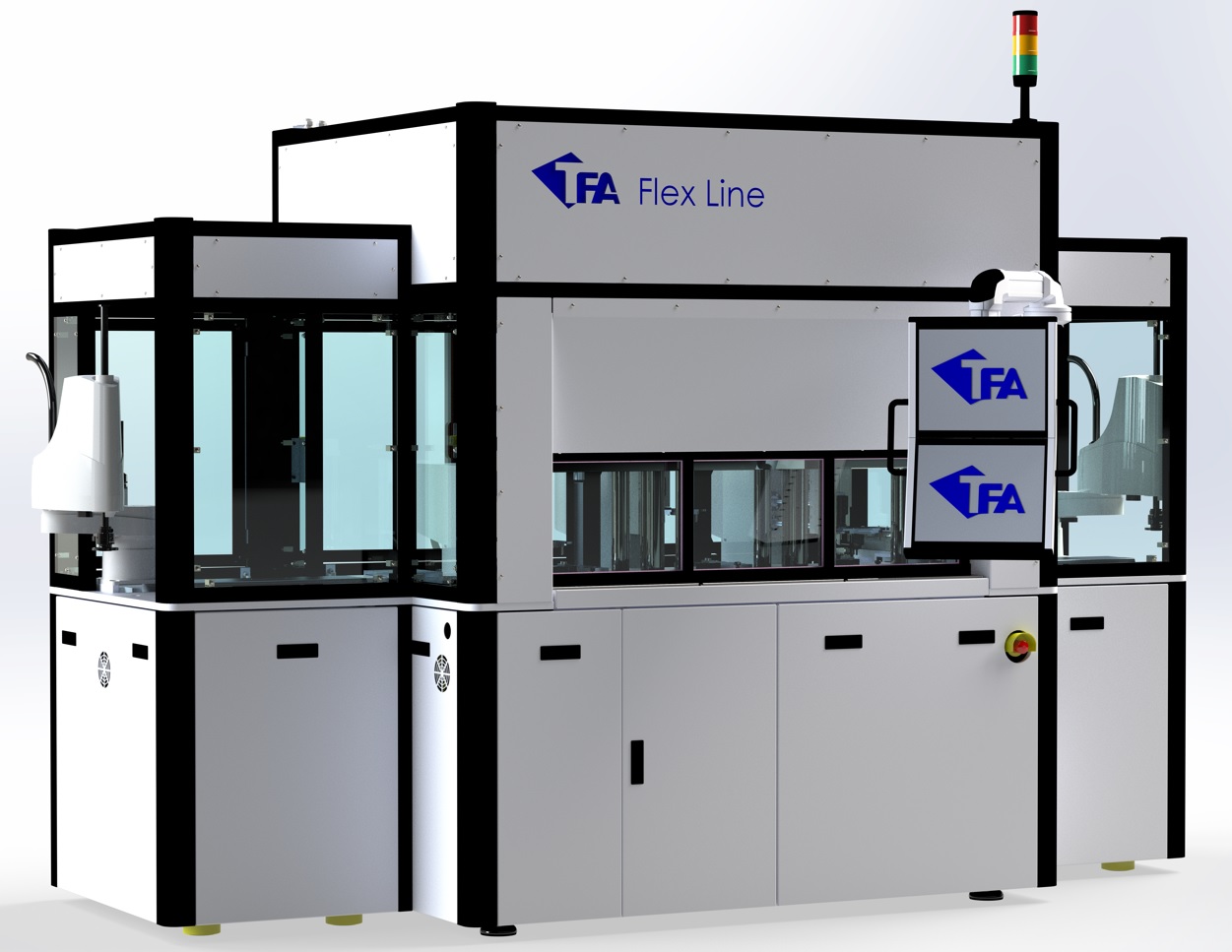

TFA Flex Line – Your Flexible Solution

The TFA Flex Line offers flexible product handling including 15-minute product changeover, high-speed handling and easy integration with other process steps. The servo-driven multiple press configuration allows for 1 to 3 individual presses (up to 100kN) and enables the best possible process sequence. It is a fully automatic high-volume trim and form system.

- High Press Force

- Force and Stroke-Controlled Presses

- High Productivity: Up to 1200 Power Modules Per Hour

- Loading and Offloading Options: Magazines, Trays, In-Line, AGV’s, SMEMA Compatible

- Optional Items: Barcode Reader, DMC Reader, Laser Marking Module, Vision Inspection Module, MES Integration

Prototype Support for Power Modules

In addition, TFA Europe offers package and leadframe design support, as well as rapid prototype tooling for manual production and product qualification. They provide customers with in-house engineering and manufacturing, sample production and quality measurements.

Their strategic partnership with Boschman Advanced Packaging Technology makes them a turnkey solution for power module development and production. Capabilities include a full range of services:

- Package Development

- Assembly Services

- Pressure Sintering Equipment & Tooling

- Transfer Molding Equipment & Tooling

- Trim and Form Equipment & Tooling

Contact Kevin Hartsoe at 215-355-2460 for more details!

Click to download the TFA Flex Line spec sheet.